FORGING AND FORMING

Billet Heating

Bar End Heating

HEAT TREATING

Gears & Sprockets

Cam Shafts

Bearings

Axles

Cylinder Bore Liners

Hubs & Spindles

Hand Tools

CV Joints

Shafts

Sintering & Tempering

MASS HEATING

Bar & Slab

Strip Heating

Wire Heating

PIPE & TUBE

Quench & Temper

Coating

Bright Anneal

CUSTOM APPLICATIONS

Crystal Growing

Bonding

Brazing

Shrink Fit

Curing & Drying

Bending

Densification

World Class

Induction Heating

Equipment

Unmatched Application Experience

Interpower Induction Services is best known for building and repairing forging coils. However, we have the experience and capabilities to design, build and repair coils for virtually all induction heating applications. Following are examples of coils

typical of those manufactured and repaired Induction ServicesForging & Forming

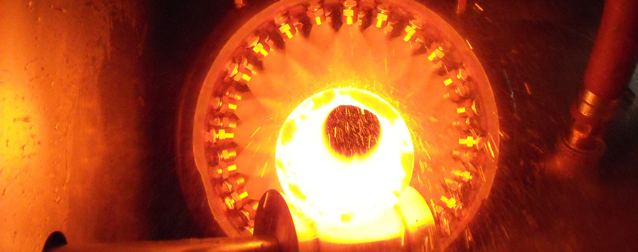

Forge-LinkSM Bar End Heating System

This compact system is one of the fastest induction bar end machines ever built. It heats up to 12 inches on the end of ? in. diam. bars to 2,350° F at a production rate of 2,400 bars per hour, at 1 piece every 1.5 seconds. The system has a 500 kW/10 kHz power supply, four coils, two bar feeders, four load pushers, and an exit conveyor with infrared temperature Accept/Reject.